Discover The Advantages Of Bernal Rp Dies: Precision, Durability, And Cost-efficiency

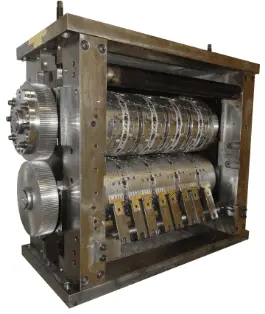

Bernal RP dies are revolutionizing the folding carton industry with their superior durability and precision cutting technology. Unlike conventional rotary dies, RP dies use advanced “shearing” blades that extend die life and maintain exceptional cut quality. This innovation results in lower costs, longer-lasting dies, and consistently high performance for your production needs.

Why Choose Bernal RP Dies?

Bernal RP Dies introduce groundbreaking technology in the folding carton industry, offering extended die life and consistent, high-quality cuts. By employing “shearing” blades rather than traditional crushing blades on both the upper and lower dies, RP dies maintain like-new cutting precision throughout their lifespan. With a range of options in steel alloys, hardening techniques, and custom designs, Bernal RP dies deliver the lowest cost per thousand for most carton volumes, tailored to your specific needs.

What Are the Benefits?

The robust design of RP dies ensures durability and minimizes maintenance, allowing operators to focus on other aspects of production. Damaged blades can often be repaired on-site, either by your team or Bernal’s repair department.

RP Dies Deliver

| • Cleanliness of cut | • High speed |

| • Durability | • In-die scrap stripping |

| • Burr-free cutting | • Creasing/scoring & embossing |

| • Low operator maintenance |

Product Applications

| • Gable Top Packaging | • Overnight Mailer Envelopes |

| • Aseptic Packaging & Pouches | • Cigarette Cartons |

| • Beverage Carriers | • Liquor Cartons |

| • Frozen Food Cartons | • Fast Food Cartons |

| • Paper Cups | • General Folding Cartons |

| • Cereal Cartons | • And more… |

- 10 to 500 million revolutions before sharpening

- Available in Solid, Partially, or Fully Segmented Construction

- Cuts materials up to .125” (3.175mm) thick

- Die diameter range: 3” to 30” (76.2mm to 762.0mm)

- Optimal cost-per-thousand at most production volumes

- Web widths from 1” to 110” (25mm to 2794mm)

- Multiple resharpening capabilities

- Suitable for materials including paperboard, high-density plastics, masonite, corrugated, recycled, and coated boards.

Why Choose Bernal RP Dies?

Bernal RP Dies introduce groundbreaking technology in the folding carton industry, offering extended die life and consistent, high-quality cuts. By employing “shearing” blades rather than traditional crushing blades on both the upper and lower dies, RP dies maintain like-new cutting precision throughout their lifespan. With a range of options in steel alloys, hardening techniques, and custom designs, Bernal RP dies deliver the lowest cost per thousand for most carton volumes, tailored to your specific needs.

What Are the Benefits?

The robust design of RP dies ensures durability and minimizes maintenance, allowing operators to focus on other aspects of production. Damaged blades can often be repaired on-site, either by your team or Bernal’s repair department.

RP Dies Deliver

| • Cleanliness of cut | • High speed |

| • Durability | • In-die scrap stripping |

| • Burr-free cutting | • Creasing/scoring & embossing |

| • Low operator maintenance |

| • Gable Top Packaging | • Overnight Mailer Envelopes |

| • Aseptic Packaging & Pouches | • Cigarette Cartons |

| • Beverage Carriers | • Liquor Cartons |

| • Frozen Food Cartons | • Fast Food Cartons |

| • Paper Cups | • General Folding Cartons |

| • Cereal Cartons | • And more… |

- 10 to 500 million revolutions before sharpening

- Available in Solid, Partially, or Fully Segmented Construction

- Cuts materials up to .125” (3.175mm) thick

- Die diameter range: 3” to 30” (76.2mm to 762.0mm)

- Optimal cost-per-thousand at most production volumes

- Web widths from 1” to 110” (25mm to 2794mm)

- Multiple resharpening capabilities

- Suitable for materials including paperboard, high-density plastics, masonite, corrugated, recycled, and coated boards.