Purpose Built Converting Systems,

Special Machine Systems, Custom Web Fed Systems

Bernal specializes in designing and manufacturing custom converting equipment tailored to your specific needs. With over 45 years of expertise, we deliver high-speed, high-efficiency continuous web converting systems for a wide range of products, supporting web widths from 1 inch to 110 inches. We seamlessly integrate our equipment with existing, new, or developmental systems. Our clients include Fortune 500 companies across industries such as packaging, medical, automotive, consumer goods, food products, batteries, disposables, and aerospace.

Why Choose Bernal Rotary Systems?

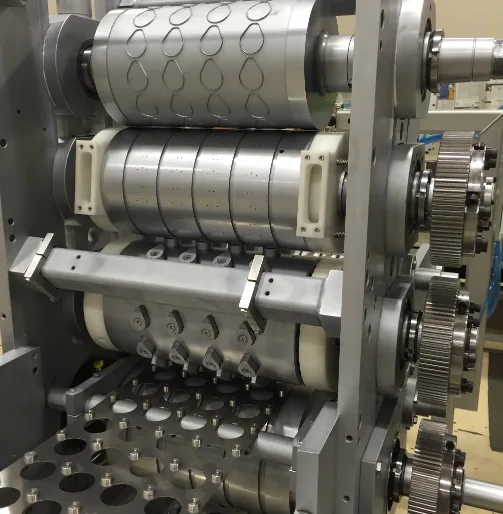

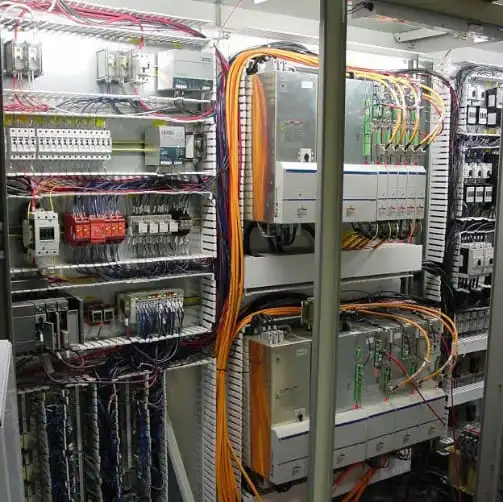

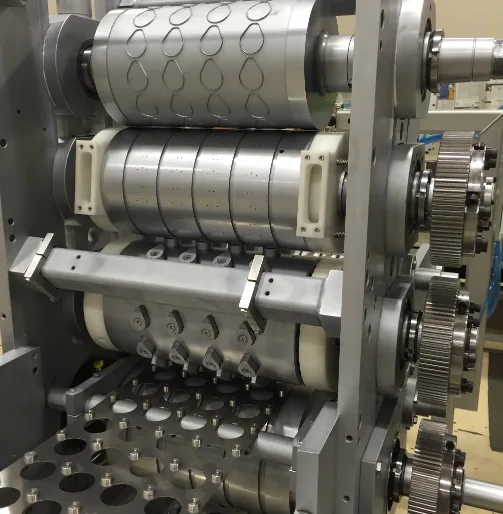

Bernal systems utilize a wide range of advanced techniques, including die-cutting, punching, ultrasonic and heat sealing, laminating, vacuum transfer, folding, counting, pouching, embossing, heating, chilling, and stacking. Our world-class service department ensures consistent production performance and support for clients across the globe.

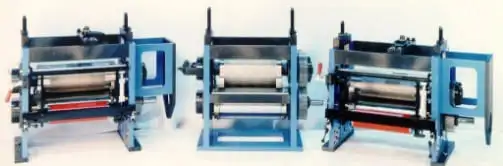

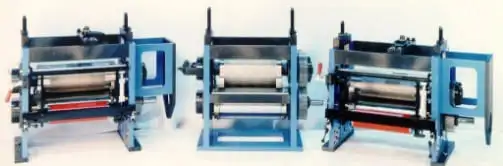

Modular Design

Bernal systems are built on a foundation of modular stations, which include both standard and custom-designed components. These modular stations, composed of subassemblies, facilitate quick product changeovers, ensuring flexibility and efficiency for a variety of production needs.

Standard Components

Bernal offers a robust selection of standard components that serve as the foundation for custom system designs. These include bearing housings, die cutting modules, infeeds, unwinds, rewinds, vacuum transfer stations, heat seal stations, delivery systems, and stackers. Our systems are designed to accommodate web widths from 1 to 110 inches and operate at speeds ranging from 10 to 1500 fpm.

- Single-source responsibility

- Inspection systems

- Food-grade systems

- High-precision cutting and assembly

- Print and part registration

- Precise tension control

- Rapid product changeovers

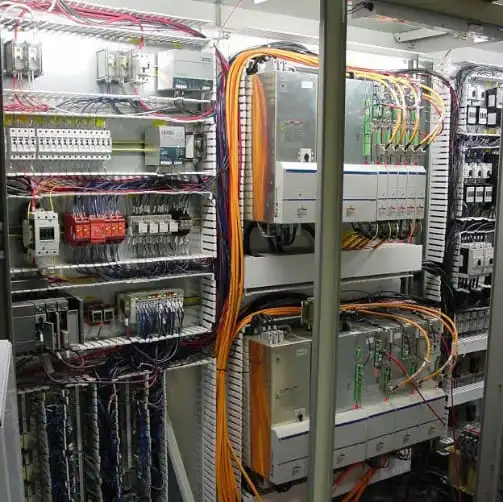

- System integration

- Compatibility with all die types

- Roll-to-roll or roll-to-finished-part processing

- Temperature-controlled oil lubrication

Why Choose Bernal Rotary Systems?

Bernal systems utilize a wide range of advanced techniques, including die-cutting, punching, ultrasonic and heat sealing, laminating, vacuum transfer, folding, counting, pouching, embossing, heating, chilling, and stacking. Our world-class service department ensures consistent production performance and support for clients across the globe.

Standard Components

Bernal offers a robust selection of standard components that serve as the foundation for custom system designs. These include bearing housings, die cutting modules, infeeds, unwinds, rewinds, vacuum transfer stations, heat seal stations, delivery systems, and stackers. Our systems are designed to accommodate web widths from 1 to 110 inches and operate at speeds ranging from 10 to 1500 fpm.

Modular Design

Bernal systems are built on a foundation of modular stations, which include both standard and custom-designed components. These modular stations, composed of subassemblies, facilitate quick product changeovers, ensuring flexibility and efficiency for a variety of production needs.

- Single-source responsibility

- Inspection systems

- Food-grade systems

- High-precision cutting and assembly

- Print and part registration

- Precise tension control

- Rapid product changeovers

- System integration

- Compatibility with all die types

- Roll-to-roll or roll-to-finished-part processing

- Temperature-controlled oil lubrication