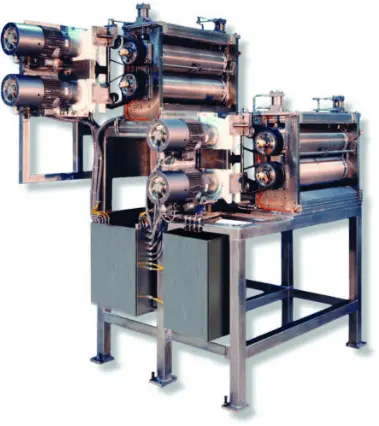

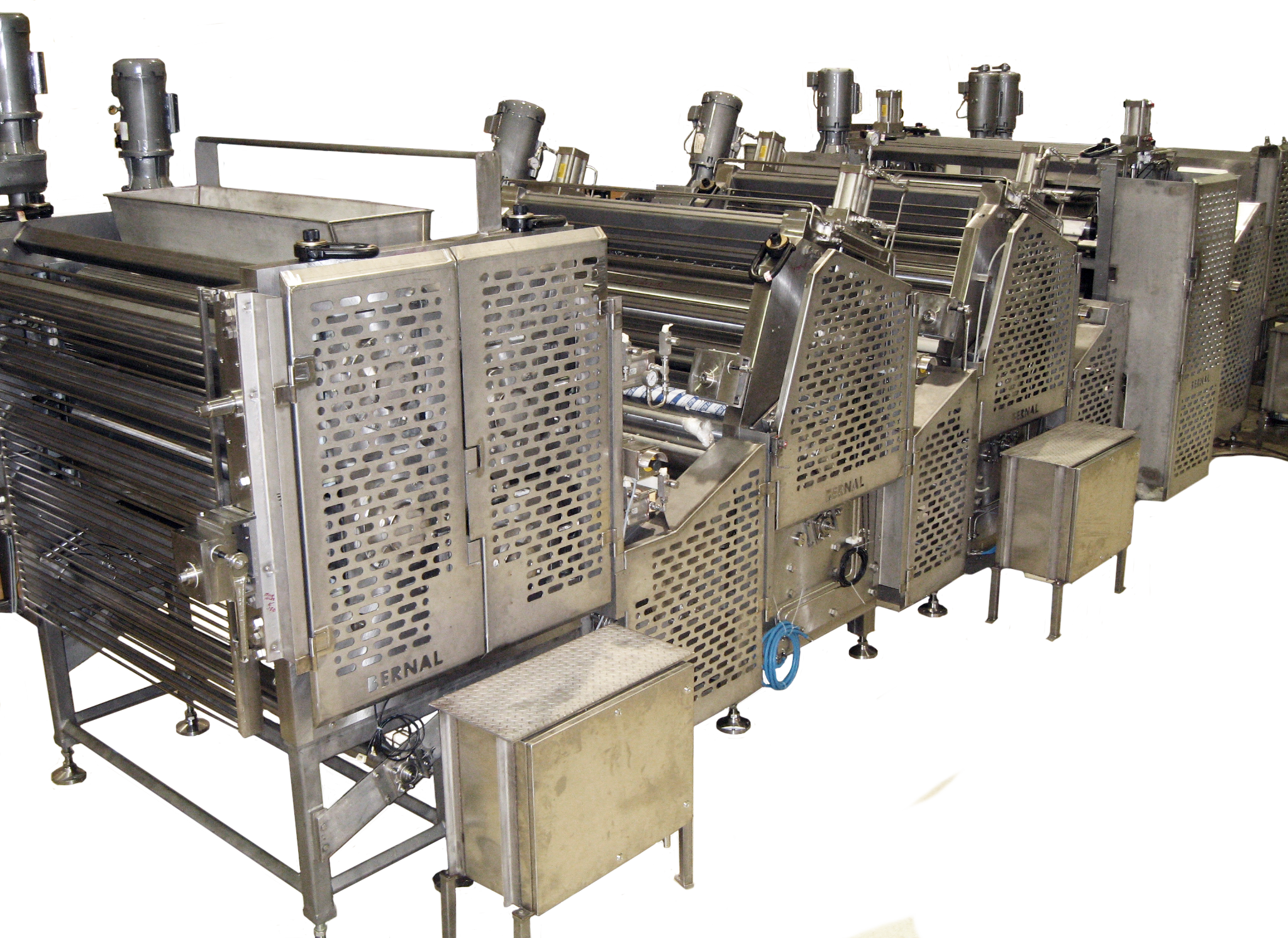

Bernal Food Processing Machinery: Precision-Crafted Solutions for High-Performance Food Production

With decades of expertise in high-speed, food-grade machinery, Bernal delivers custom sheeters, cutters, and modular systems that ensure precise, efficient processing across a range of food products. Supported by a world-class engineering team, our turnkey solutions are designed for reliability and superior performance in demanding food industry applications.

Bernal Food Processing Machinery:

Precision Sheeting, Cutting & Custom Solutions

Bernal specializes in designing and manufacturing custom food-grade systems tailored to meet specific processing needs. With over 45 years of experience in high-speed, continuous web and sheet processing systems, Bernal’s solutions drive efficiency and precision across a wide range of food products. Supported by a dedicated global service department, Bernal ensures reliable production and seamless operation.

- Food-grade systems in both standard and custom designs

- Modular roll stands for flexible setups

- Backed by an experienced, innovative engineering team

- Suitable for processing products such as snack foods, liquid packaging, drink pouches, breakfast cereals, and coffee packaging

- Compatible with diverse dough types, including potato, rice, and corn

- Equipped with high-resolution servo controls and drives for precise operation

- Solid and segmented food-grade tooling options

- Tools crafted from food-grade plastic and stainless steel

- Fully washable, sanitary designs

- Precision tolerances for accurate cuts and shapes

- Advanced CAD/CAM, CNC, and CMM machining processes

- Pneumatic transfer tooling for product and regrind

- Custom designs to meet unique processing requirements

- Temperature-controlled rolls for optimized cutting

- Complete turnkey systems and support from a skilled engineering team

Bernal Food Processing Machinery:

Precision Sheeting, Cutting & Custom Solutions

- Food-grade systems in both standard and custom designs

- Modular roll stands for flexible setups

- Backed by an experienced, innovative engineering team

- Suitable for processing products such as snack foods, liquid packaging, drink pouches, breakfast cereals, and coffee packaging

- Compatible with diverse dough types, including potato, rice, and corn

- Equipped with high-resolution servo controls and drives for precise operation

- Solid and segmented food-grade tooling options

- Tools crafted from food-grade plastic and stainless steel

- Fully washable, sanitary designs

- Precision tolerances for accurate cuts and shapes

- Advanced CAD/CAM, CNC, and CMM machining processes

- Pneumatic transfer tooling for product and regrind

- Custom designs to meet unique processing requirements

- Temperature-controlled rolls for optimized cutting

- Complete turnkey systems and support from a skilled engineering team