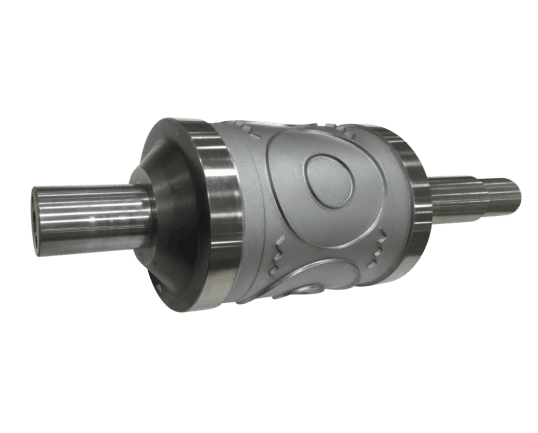

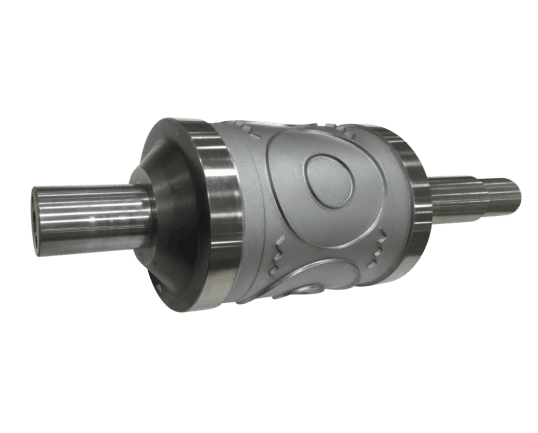

Bernal Crush Cut Rotary Dies: Precision, Durability, and High-Speed Performance

For decades, Bernal has set the standard in rotary die technology, delivering unmatched precision and longevity. Our Crush Cut Rotary Dies are engineered to provide the cleanest cuts at the highest speeds, making them the ideal solution for continuous web material applications across various industries, from packaging to medical supplies. Discover the features that make Bernal dies an industry leader.

Why Choose Bernal Crush Cut Dies?

Bernal pioneered the solid-hardened rotary die in the late 1960s, developing a proprietary wedge-type cutting edge on a solid-hardened cylinder using Electrical Discharge Machining (EDM). Since then, Bernal has delivered thousands of rotary dies renowned for high-quality cuts, exceptional speed, and compatibility with diverse materials and products—ranging from folding cartons and medical bandages to printed circuits, batteries, and even snack foods.

Outstanding Features and Benefits

- Machine Sharpening: Ensures precise, clean cuts with each use.

- Solid Steel Construction: Robust and durable for extended use.

- Segmented Options: Available in partially or fully segmented designs.

- Quick-Change Capability: Allows for fast setup and adjustments.

- Fully Hardened: Built to withstand rigorous, high-speed operation.

- Scrap Stripping: In-die scrap removal for efficient processing.

- Precision Cutting Tolerances: Achieves exacting shape accuracy.

- Cutting Edge Accuracy: Within .001” (.025mm)

- Web Width Range: 1” to 110” (50mm to 2794mm)

- Die Diameter Range: 3” to 40” (76.2mm to 762.0mm)

- Run-Out Accuracy: Within .0001” (.0025mm)

- Hardness: 60-62 Rc

- Resharpening Capability: Up to 5 times

- SBS Board: 40 million revolutions

- Poly Board: 80 million revolutions

- Lead: 8 million revolutions

- PVC: 5 million revolutions

- Sandpaper: 2 million revolutions

| • Poly Board | • Recycled Board |

| • Cloth | • Dough |

| • Lead | • Non-Woven Materials |

| • Sandpaper | • Laminates |

| • Polypropylene | • Fiberglass |

| • Paper | • Copper |

Why Choose Bernal Crush Cut Dies?

- Machine Sharpening: Ensures precise, clean cuts with each use.

- Solid Steel Construction: Robust and durable for extended use.

- Segmented Options: Available in partially or fully segmented designs.

- Quick-Change Capability: Allows for fast setup and adjustments.

- Fully Hardened: Built to withstand rigorous, high-speed operation.

- Scrap Stripping: In-die scrap removal for efficient processing.

- Precision Cutting Tolerances: Achieves exacting shape accuracy.

- Cutting Edge Accuracy: Within .001” (.025mm)

- Web Width Range: 1” to 110” (50mm to 2794mm)

- Die Diameter Range: 3” to 40” (76.2mm to 762.0mm)

- Run-Out Accuracy: Within .0001” (.0025mm)

- Hardness: 60-62 Rc

- Resharpening Capability: Up to 5 times

- SBS Board: 40 million revolutions

- Poly Board: 80 million revolutions

- Lead: 8 million revolutions

- PVC: 5 million revolutions

- Sandpaper: 2 million revolutions

| • Poly Board | • Recycled Board |

| • Cloth | • Dough |

| • Lead | • Non-Woven Materials |

| • Sandpaper | • Laminates |

| • Polypropylene | • Fiberglass |

| • Paper | • Copper |