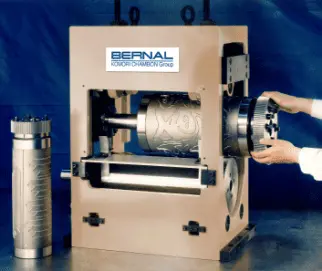

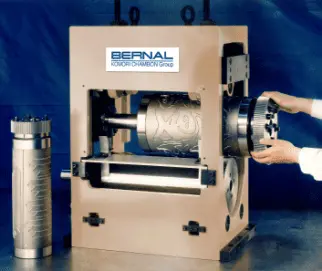

Bernal Die Cutting Modules & Cassettes: Unmatched Precision and Performance for High-Speed Applications

Bernal’s die-cutting modules and cassettes are engineered to deliver superior precision, longevity, and efficiency across various industrial applications. With over 45 years of expertise, our modules are crafted to ensure seamless operation, providing custom solutions and advanced scrap management for optimal die-cutting results. Discover the Bernal difference in quality and performance.

Bernal Die Cutting Modules & Cassettes: Precision-Engineered for Maximum Performance

For over 45 years, Bernal has delivered die-cutting modules that enhance die performance through robust design and precision engineering. Each module is crafted to achieve the highest accuracy and reliability, supported by an advanced machine shop that ensures industry-leading quality. Available in standard and custom designs, our modules support diverse applications, from folding cartons and medical supplies to food packaging. We also provide ongoing inspection and service, maintaining your module in top condition and offering quick replacement from our extensive spare parts inventory. Bernal is proud to provide our premium modules and rotary tooling solutions for users of competitors’ equipment. Contact us today to learn how we can support your die-cutting operations.

- Integrated in-module pin stripping

- Quick changeover capability

- Extended die-life

- Compatibility with all rotary die types

- Spare parts readily in stock

- Single-source responsibility for die and module

- Rigid box construction

- Precision bearing housings

- Robust stripping comb assemblies

- Temperature-controlled oil and grease lubrication

- Adjustable side, rotational, and skew-bearing

- Options for journaled and shaftless versions

- Single-Slot Modules: These are equipped with four bearing housings for mounting upper and lower tools and are available with or without in-module stripping capabilities.

- Dual-Slot Modules: Ideal for applications requiring precise registration between tooling stations, dual-slot modules allow for the simultaneous setup of two toolsets. They come in roll-in styles for easy mobility within the facility.

- Custom Modules: Bernal can create custom modules to fit other manufacturers’ rotary-cutting systems, including food-grade stainless steel and custom-sized modules to meet specific operational needs.

Bernal Die Cutting Modules & Cassettes: Precision-Engineered for Maximum Performance

- Integrated in-module pin stripping

- Quick changeover capability

- Extended die-life

- Compatibility with all rotary die types

- Spare parts readily in stock

- Single-source responsibility for die and module

- Rigid box construction

- Precision bearing housings

- Robust stripping comb assemblies

- Temperature-controlled oil and grease lubrication

- Adjustable side, rotational, and skew-bearing

- Options for journaled and shaftless versions

- Single-Slot Modules: These are equipped with four bearing housings for mounting upper and lower tools and are available with or without in-module stripping capabilities.

- Dual-Slot Modules: Ideal for applications requiring precise registration between tooling stations, dual-slot modules allow for the simultaneous setup of two toolsets. They come in roll-in styles for easy mobility within the facility.

- Custom Modules: Bernal can create custom modules to fit other manufacturers’ rotary-cutting systems, including food-grade stainless steel and custom-sized modules to meet specific operational needs.